-40%

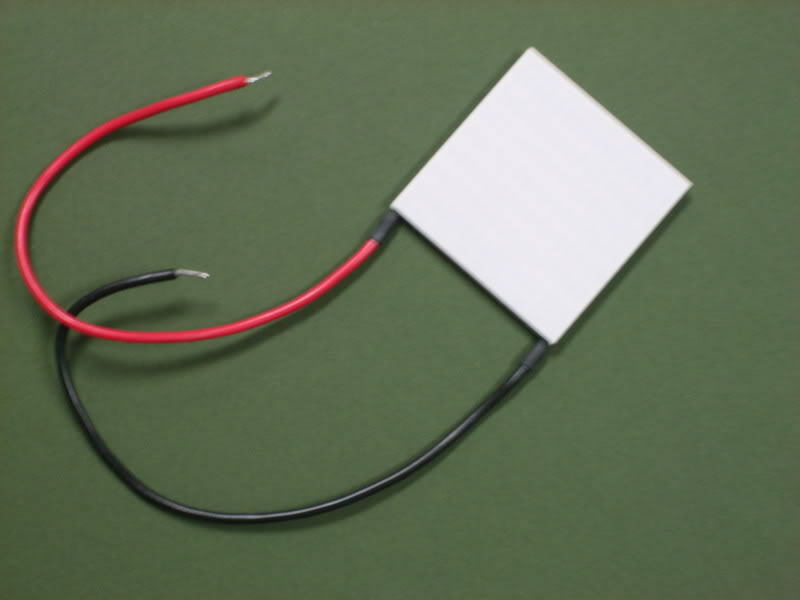

Thermoelectric Generator TEG - 40mm Seebeck Power Generation Element - NEW - USA

$ 18.47

- Description

- Size Guide

Description

Thermoelectric Generator TEG ModulePower Generation

- Seebeck Element

40mm x 40mm x 3.4mm

Model Seebeck

T-12708-40

Quality - Performance - Reliability

from the USA

CONVERTS HEAT INTO ELECTRICITY USING THE SEEBECK EFFECT

FREE ELECTRICITY FROM WASTE HEAT

THIS AMAZING SEMICONDUCTOR DEVICE CAN BE USED TO GENERATE POWER FROM WASTE HEAT or WHEN POWERED WITH A DIRECT CURRENT IT WILL ACT AS A HEATPUMP AND PROVIDE EXTREMELY COLD TEMPERATURES AT ONE SIDE MOVING THE HEAT AWAY TO THE OTHER SIDE.

Designed specifically for power generation. This 40mm power generator is sealed for moisture protection and contains thermal elements formulated for optimum Seebeck power generation.

Shipped direct from the USA.

Each module contains 254 thermal elements formulated for optimum Seebeck (power generation).

You can expect output in the range of 0.5 to 2.0 VDC and 0.1 to 1.2 Amps depending on the temperature differential maintained across the two faces of the module. To optain maximum output you would need a temperature differential in the range of 100-120 deg C.

ALWAYS USE A THIN COATING OF THERMAL GREASE BETWEEN THE MODULE AND MOUNTING SURFACES. ATTEMPTING TO USE THE MODULE WITHOUT THIS HIGH THERMALLY CONDUCTIVE INTERFACE MATERIAL WILL RESULT IN POOR PERFORMANCE AND POSSIBLE DAMAGE TO THE DEVICE. EXCEEDING THE MAXIMUM EXPOSURE TEMPERATURE WILL SEVERELY DAMAGE THE MODULE.

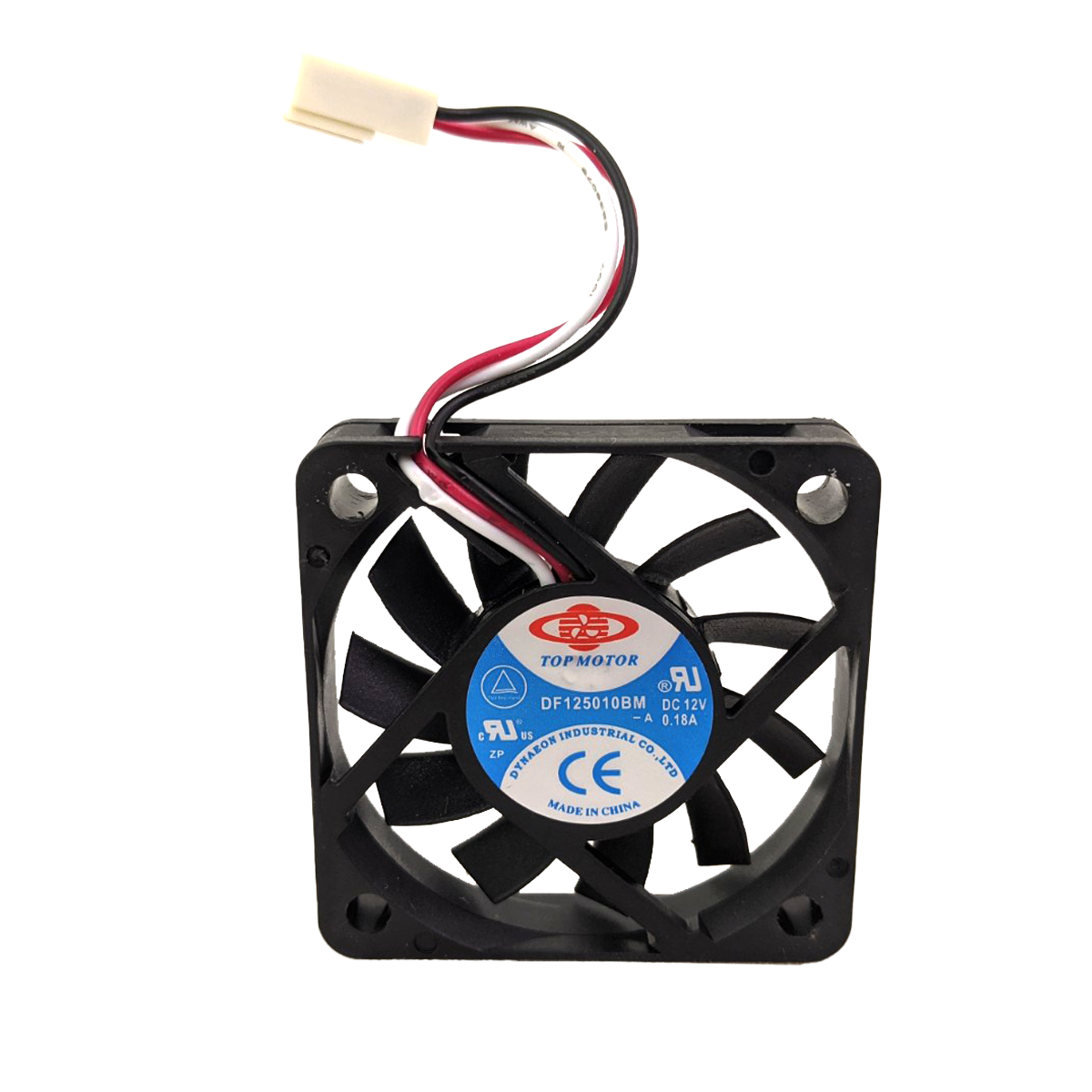

Important Note Regarding Wood Stove Fans

If your fan has a defective motor replacing the TEG module (thermo electric generator)

will not

fix the problem. The TEG module is the device which converts heat to electricity. It is sandwiched between the upper and lower sections of the aluminum extrusions. This allows heat to flow from the hot base through the TEG module and to the upper fins where the heat is then dissipated in the air flow. These fans operate in a high heat environment which is hard on both the motors and the TEG modules. Both items can and do go bad although the TEG module being exposed to the highest temperatures is the component that fails more often. You can test your motor using a common household battery to determine if it is working correctly before you conclude that the TEG module needs replacement.

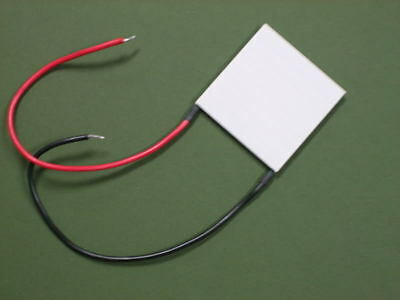

When replacing the TEG module be sure to apply a thin layer of thermal grease on both faces of the new TEG module prior to assembly.

This high thermal conductivity interface material is necessary to achieve optimum performance and to extend service life.

Thermal grease is generally available at any store that sells computers and/or computer components.

Stores like Best Buy sell thermal grease and it can also be found online at eBay or many other sites.

Use a straight edge to apply and spread the thermal grease across the entire surface of the TEG.

I’ve found that using the edge of a credit card works best.

Gently press and rotate the TEG against the mounting surface of the top heatsink.

This will help “seat” the module with full surface contact.

Re-wire the new TEG module to the fan motor.

You can either solder the leads to the fan motor or splice them to the short length of lead wire left from your old TEG module.

As you re-connect the top half of the fan assembly (heatsink side) to the fan assembly base make sure you have remembered to apply thermal grease to the bottom face of the TEG module.

Again, gently press and rotate to “seat” the TEG against the mounting surface.

Be careful not to damage the TEG during the re-assembly process.

TEG modules are strong in compression but they are weak in shear so

do not

pinch or over-torque.

Use a bolt pattern when tightening the two halves of the assembly together (similar to how you would mount an automobile tire).

This will prevent pinch points that could fracture the TEG and will result in uniform compression.